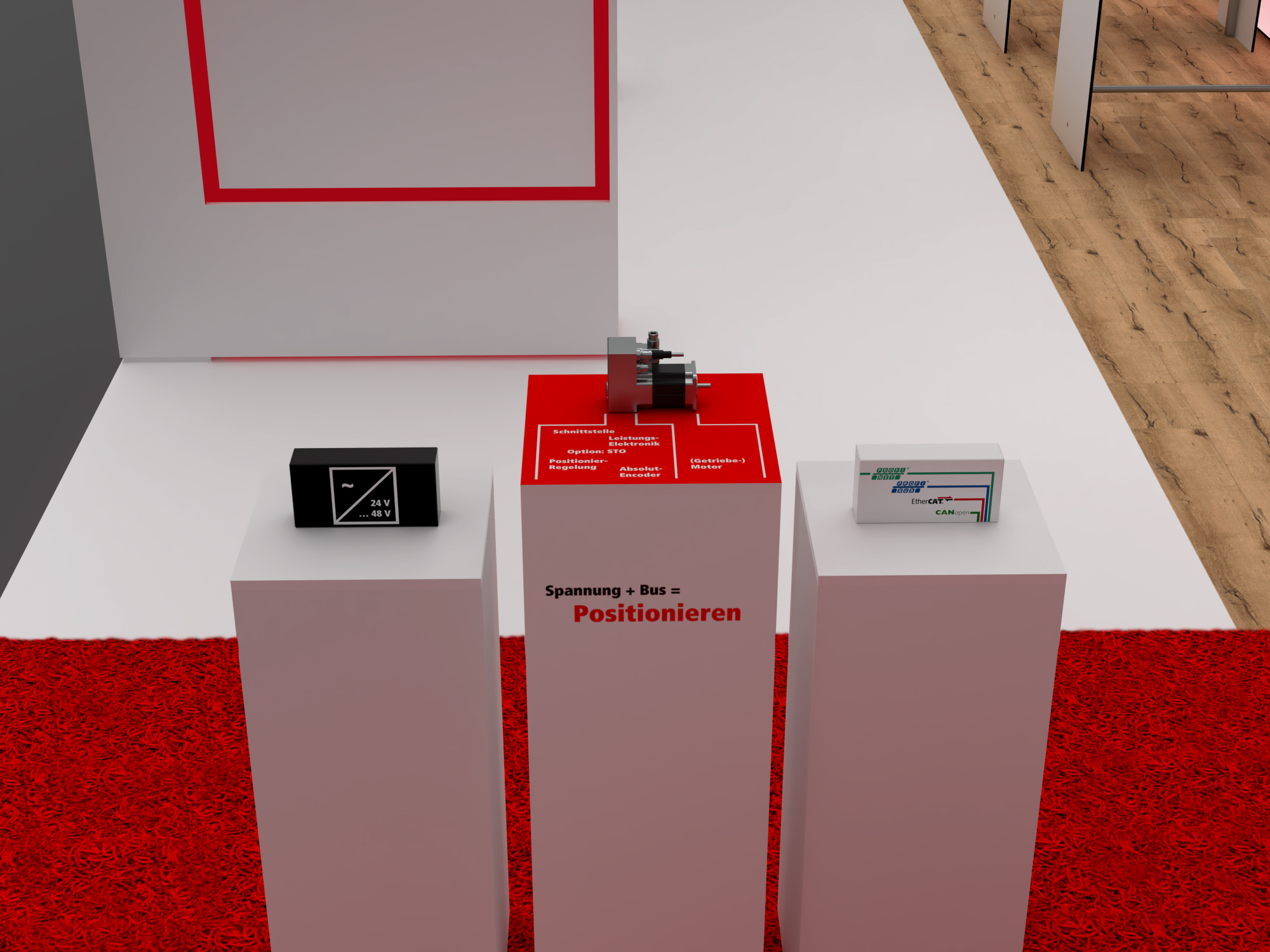

Voltage + fieldbus = positioning

Power supply and fieldbus connection – this is all that‘s required to implement actuating and positioning tasks in your system with encoTRive compact drives. The concept of gear motor with integrated positioning controller offers numerous advantages:

Advantages for the switch cabinet

_ No space consumption and no heat emission by the drive electronics

Simple wiring

_ No EMC-critical motor cables need to be laid

_ Thanks to the extra low voltage supply, all components and connections can be touched

Absolute position available at any time

_ No reference runs required

_ Reference initiators and associated wiring not necessary

Easy implementation of machine safety

_ STO (safe torque off) optionally integrated

Tailored to your application

_ Broad range of motor and gear variants

_ Wide power range from 50 to 600 watts

_ Assistance with selection and design by our drive specialists

Advantages for the application software

_ Control of different types identical within a fieldbus

_ Changeover or mixed operation between Profibus and Profinet possible with minimum effort

_ Example PLC projects available

Problem-free use overseas

_ Optionally available as a UL-Recognized Component

A look at our archives

Brochures

News

Navigation

- New solutions 2026

- Absolute rotary encoders size 58mm

- Remote interface box CIB2X

- Functional Safety

- Rotary encoders incremental

- Solutions for challeging enviroments

- Wire lenght Encoders

- Linear absolute encoders – Magnetostriction

- Linear encoders – Customer specific solutions

- LASER

- Motion

- Voltage + fieldbus = positioning

- Configuration example

- Migration – Interfaces

- Integrated safety technology

- Customer-specific solutions

- Special exhibit Notion – 5 PCs

- notion.PLC – full automation solution by TR

- Automation

- Unidor Piezo Control

- Unidor Sensors & Controls